I have been cranking through the work on this as fast as I can in preparation for

World Fatbike Day on December the 7th. Young

Dave mentioned this when I went in to pick up the bits for the 2x9 drivetrain I intended to fit to the beast. I took this on board as I figured what better way to celebrate than with the birth of a new fatbike. Not a finished fatbike mind, but hopefully a functional one.

I have hit a couple of snags though.. mostly involving my utter noobness when it comes to dérailleur setups. Initially I had thought I would just fit the standardish 3.8" tyres, but fairly early on in the build when I saw just how awesomely fat the

Big Fat Larry's are, I decided I needed to have them. Unfortunately the last time I paid any real attention to trivial things like chainlines was before this decision, so when it came time to attach the driving bits it was immediately apparent that the tyre was going to hit the chain for nearly every useful gear when in the small front sprocket.

I was a bit put out by this failure of Shimano to accommodate my requirements, but after a modicum of thought and calculation of ratios I decided that a 1x10 setup could be made to work, and as long as I didn't use the bike for land speed record attempts I would be pretty much ok. I then ordered a 32T downhill front ring, a 11-36 cassette and a nice dérailleur-shifter combo. This gives me a lowest gear pretty much equivalent to the Disc Truckers second lowest gear, which should be enough for getting up hills. These bits may take a week or 3 to arrive and I wanted to be mobile for the 7th, so I bought a single speed Kit off a very pleasant TradeMe chap called Dan. I suspect I could have talked to Dan a lot longer that would be appropriate for a supposed work day I was bunking off from, plus I was scared he would show me other bike parts and I would be powerless to resist, so I made my escape. I am now waiting on a single speed tensioner to make the thing actually rideable. Fingers crossed for this week.

The seatpost was another wee snag, I assumed that the ID of the seatpost was going to be 27mm according to the specification, which meant a simple job of reaming it out to 27.2 was going to be the go. Upon inspection the seatpost tube actually measured 26.6mm and it seemed a shame to thin things out too much, especially as

Canyon flips will soon be part of my repertoire no doubt. I could only find a second hand Thompson Elite Inline seatpost on Trademe that was smallish enough at 26.8, so I grabbed it figuring it would do for now, and if it is too rough I would find something else later. In the mean time Dave leant me a vintage MTB post that at least allows me to get a seat on the thing.

I also had a wee beg on

Vorb and borrowed some useful bits from a chap called Gumby - I can't tell you how useful that stuff has been - I owe that man a beer. I also did the same from an old workmate called Mike, and between the two suppliers I have sorted an acceptable cockpit sizing.

So anyway, today I decided I was going to ride it no matter what, even though I had a droopy chain, so I chucked the seat from my single speed onto it, checked everything over and rode it up the road. It was hilarious fun even though the chain meant I couldn't put any real power down. It feels pretty good, with no obviously bad handling characteristics or waywardness. It is a bit hard to say though so I shall wait till I have used it in anger. The main thing I notice is the incredible thrumming noise from those tyres...

|

| I dub thee 'The Fatness' |

|

| I am gagging for that chain tensioner to arrive |

|

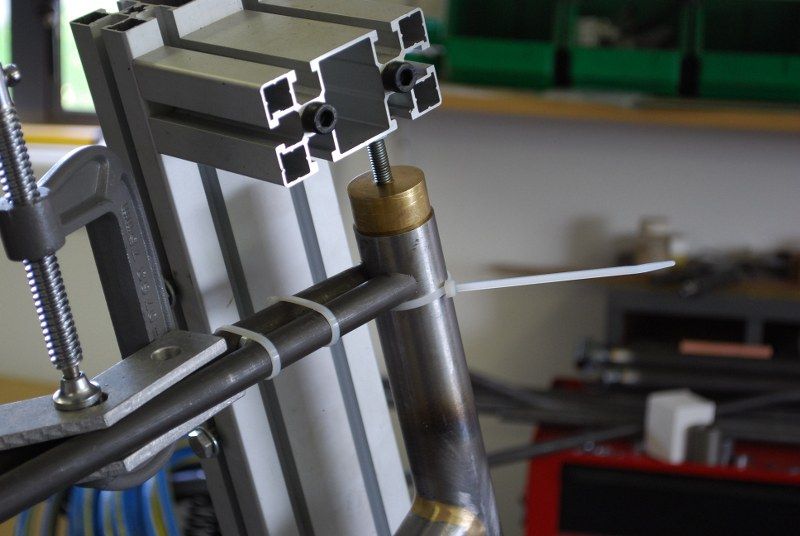

| The offending drivechain area |

|

| A probably illegal use of the local currency |

|

| That vintage Brooks actually looks pretty good on The Fatness |

So there is still quite a lot to do, I have ordered many many brazons from Ceeway that will allow me to tidily zip tie the cables to the frame. This system is on the disc trucker, and as I am using full length cable sheathing it makes a lot of sense. Then sorting the drivetrain and after that some testing is in order, and then many hours of cleanup before I get it coated. I am not sure exactly what this will be yet, but a decision is getting closer...