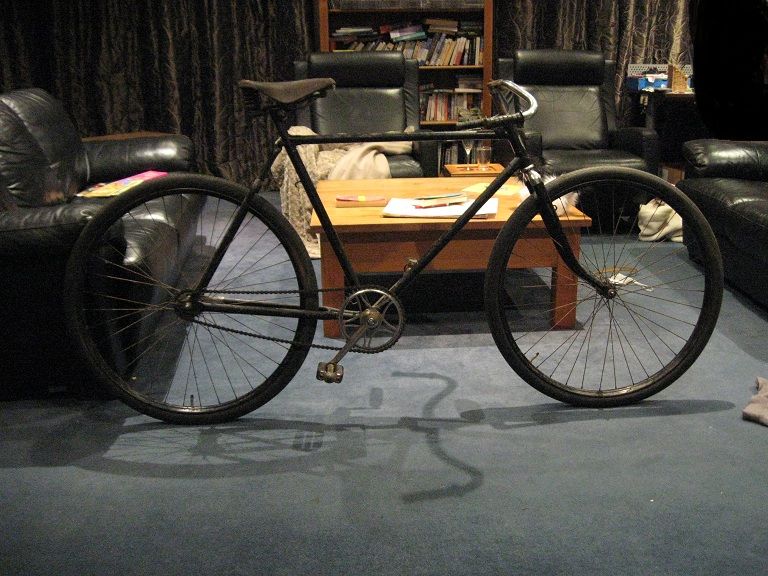

One of the more useful distractions has been this thing, which I got as a freebie along with the Gazelle. It has been languishing in bits in my garage, but I thought I had better put it together and see what the story was, and was pleasantly surprised with what resulted;

It is German and probably from the late 40's/early 50's. Hard to tell as there is not much info out there. Actually there probably is and I should clarify my position here; after 4 minutes of googling, not much info turned up. I imagine speaking German might help in this search though. It has some interesting features - square taper cranks for a start, and a sweet clampless attachment for the coaster brake arm. The tyres say 28 x 1.75, but english 28" tyres do not fit, so I assume it has 28"/700c or some deeply strange European variation thereof. The original German made tyres were still in basically functional condition, so I left them on. It also required a 24mm seatpost, so I had to make one to suit as this was missing. Making this has taught me no end of interesting stuff about my lathe and the auto feed....mostly that engaging the fast and slow feeds at the same time is a bad idea, and how to replace shear pins in the drive for the auto feed..... oops.

The Mifa was way too small for me so I have since sold it to one of the tweed boys, hopefully it will give good service.

And onto the framebuilding. A very nice man called Shaun lent me the Paterek DVD's, which made for some hours of fascinating watching. The main result of this was half a day spent die grinding all the lugs to give the correct clearance to the tubes, and a much clearer idea of what to do and when to do it during the brazing process.

Now, a couple of weeks ago the fork jig fairy visited me in my sleep and pointed out that quite a few weeks had passed since I had received the fork jig, and that there was little sign of me actually using it to braze forks with, and (very nicely) asked for it back so he could use it to sort out the backlog of forks he had to build. He made some quite valid points, so I obligingly handed it back. I then got to thinking how nice it would be to have a fork jig of my very own, and then I got to thinking about how sweet it would be if it were part of the frame jig itself.

So today I spent some quality time with the Grayson and ended up with this;

Now I just need to spend a few more hours sorting out the axle attachment, which I will try to make adjustable so that other fork geometries can be built as well...

One of the reasons for slow progress has been the new dropouts. I decided to make these out of 4130 chromoly, and after a wee bit of investigation I found that P20 tool steel is a subtype type of 4130. This is a good thing because P20 is a very common material used in injection moulding tools, and in the course of my work I have quite a lot to do with this sort of thing, and indeed I know many toolrooms that have stacks of it lying round. After some discussions with my favourite machine shop I decided that it would be best to get them to CNC the dropouts for me, because they would then be exactly right first time... and these should be ready on Monday, I can make then make final prep for brazing. I am probably going to hire a gas plant over the weekend, so I would like to get everything ready and do it in one big hit.

Actually building this thing is getting scarily close...