However in my opinion, wasting time getting things wrong is the prime causes' way of preparing you to eventually get it right, so I have decided to have another go...

The initial design with the standard dropouts was going to require some tweaking of the bottom bracket chainstay angles to get the fit right, and once I set the new dropouts up in the jig it was pretty obvious that getting a few degrees off center angle on the chainstays was not going to be a problem.

So last night I sat down for a CAD session at the computer (my wife was gallivanting around the frankly scary pub selection in Addington with her

This design has the benefit of the adjustment being inside the frame, plus there are less curves and angles, making it more pleasing to the eye in my opinion. The only real issue is the adjustment screw taking a significant amount of meat away from the connection between the chainstay and the seatstay, but I can always beef this up some more, we will see. I call this design the frogmouth MkII, for obvious reasons.

Now I need to source some 8mm 4130 steel, and get to cutting...

I have been thinking hard about the brakes for this bike, initially I was intending to put standard MTB brakes. this would be ok but maybe not that pretty, I think that these might be a better option;

They are nice, if a little bit hard to get hold of in NZ.

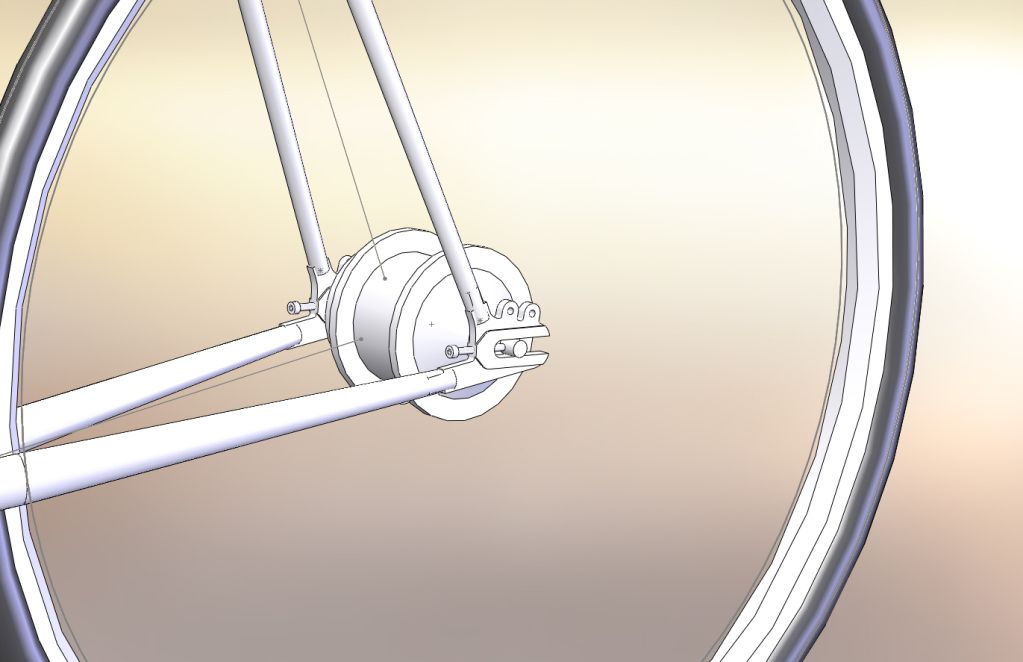

The Gazelle has continued as it started, ie being extremely truculent no matter what I try to achieve with it, however the journey is fast drawing to a close. So close in fact that I foolishly decided to ride it to work yesterday. There were a few teething troubles (I needed to stop at least 4 times to adjust the gears, tweak the guards, clean my undies after trying to stop in traffic). I did however get a scalp on my ride home, but this was simply because I had maxed my FCN, so everything on 2 wheels was fair game.

Still it was fun, and I took a couple of pics to mark the occasion;

Those wheels where very time consuming, I bolloxed it up the first time not realising that the spoke holes were offset, plus I got the lacing wrong, plus the rims turned out to have larger than standard nipple holes, plus the spoke lengths were not quite right, etc etc... Dave very kindly sorted things out for me though, he is a solid chap.

I still need to shorten the brake lever arm at the front to make the brakes actually perform their function, and maybe find a new gear cable. And probably sort out a chain guard. And maybe find a pannier for it. Apart from that I think it is looking pretty swish and rather gentlemanly, don't you think?