All went well and it was a rather enjoyable outing, I even met someone who had actually been reading this blog which was amusing.... however during the event I noticed a very slight hairline crack on the top brazed joint of the stem. Clearly this needed sorting, as historically my face doesn't deal very well with impacting the ground from nearly 2 meters up, and I have a pretty robust avoidance policy in these situations.

|

| Hard to see the actual crack, but it has obviously propagated from that wee pit |

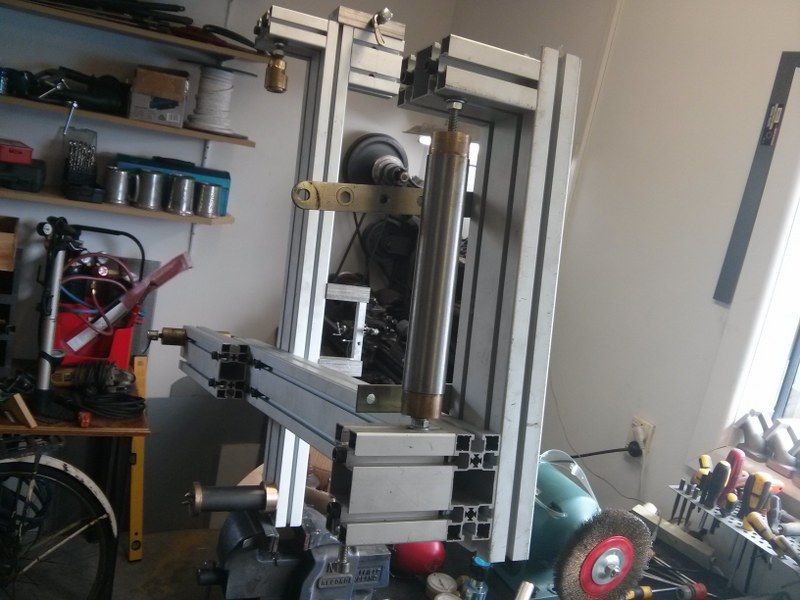

After I gingerly rode home I pulled the stem off and set about finding a temporary replacement until I could sort it further. the only thing I could find in my box of goodies was an old Ace stem with roughly the right geometry, but unfortunately it had a 25.4mm bore, and the VO bars are 26mm. I had a think about how I could sort this out using what kit I had in the garage. Serendipitously I discovered almost immediately that the Grayson has a morse taper in the spindle which means you can mount a drill chuck in there. This meant that I could just possibly pretend that it was a mill not a lathe, and bodge ensued;

|

| Not pretty or particularly rigid, but it did work |

|

| I made a special boring tool for the job from a bolt and a double height nut, incredibly hard to adjust but again, it worked well enough |

This was all good fun and meant I could actually ride the bike to work again, but clearly this was just a distraction from the real excitement of the week;

|

| Shiny things, yesterday |

|

| Mmmm, the fatness of it all. |

The keen eyed amongst you may notice that there are no seat stays or top tube in the parts collection, this because the design harks back to a BMX I had when I was 12 or so which had twin top tubes all the way from the head tube back to the dropouts. This bike was fully chromed and the envy of all who spied it, at least in my mind it was... If I can capture a wee bit of that misty eyed goodness in this frame then I will have succeeded. The tube for that and the forks is currently on order from Lianne, I should see it in the next couple of weeks.

So this weekend was given over to modifying the frame jig to suit the new geometry. This is where noob assumptions have caught me out - I never imagined I would be making a frame with a 100mm wide bottom bracket, a 170mm rear dropout spacing, a 135mm front spacing, a 1-1/8th threadless steerer or even a frame with different head tube/seat tube angles. I spent considerable time drilling and filing things to get the jig to fit the geometry, then started to sort out the mounting points;

|

| The headtube and seat stay just needed the top mounts slipping down a tad |

|

| Bottom Bracket mounting needed a new inner mount to get the correct spacing |

So the frame will either be Tig welded or fillet brazed, I haven't yet decided that either.... I have just bought a new welder that is a combo Mig/Tig, but the Tig function is pretty unsophisticated compared to some machines I have used in the past, so requiring a wee bit of skill to get a sweet joint. Balancing this is my slightly increased fear of fillet joints cracking, a recent experience of which has tainted things a bit. Fillet brazing is probably going to be the way though, I shall just pay a lot more attention. The forks I definitely will Tig, the many kilograms worth of Chumly they will see has already decided that....

A lot to think about then, and much more to discuss - gears, wheelsets, brakes etc....

Are you going to destructo test that stem now?

ReplyDeleteThe last (only) time I upsized a stem I used an ajustable reamer. Jammed something in ther slot to stop it chattering.

Yes, I will have a good look at it to see what it up, but I remember that at one point during the fitting up of the stem things were a wee bit tight and I inadvertently bent up the top half of the clamp, so that may have contributed. I have been looking for a decent set of adjustable reamers for a while, but it all comes down to spending money, and hiding that spend from my wife ;-) I will need some reamers soon regardless, but I have my heart set on a mill or mill lathe combo - I desperately need a mill if only to speed up the mitering process, and I have hit the functional limits of the Grayson a few too many times now...

Delete